New

Highcon

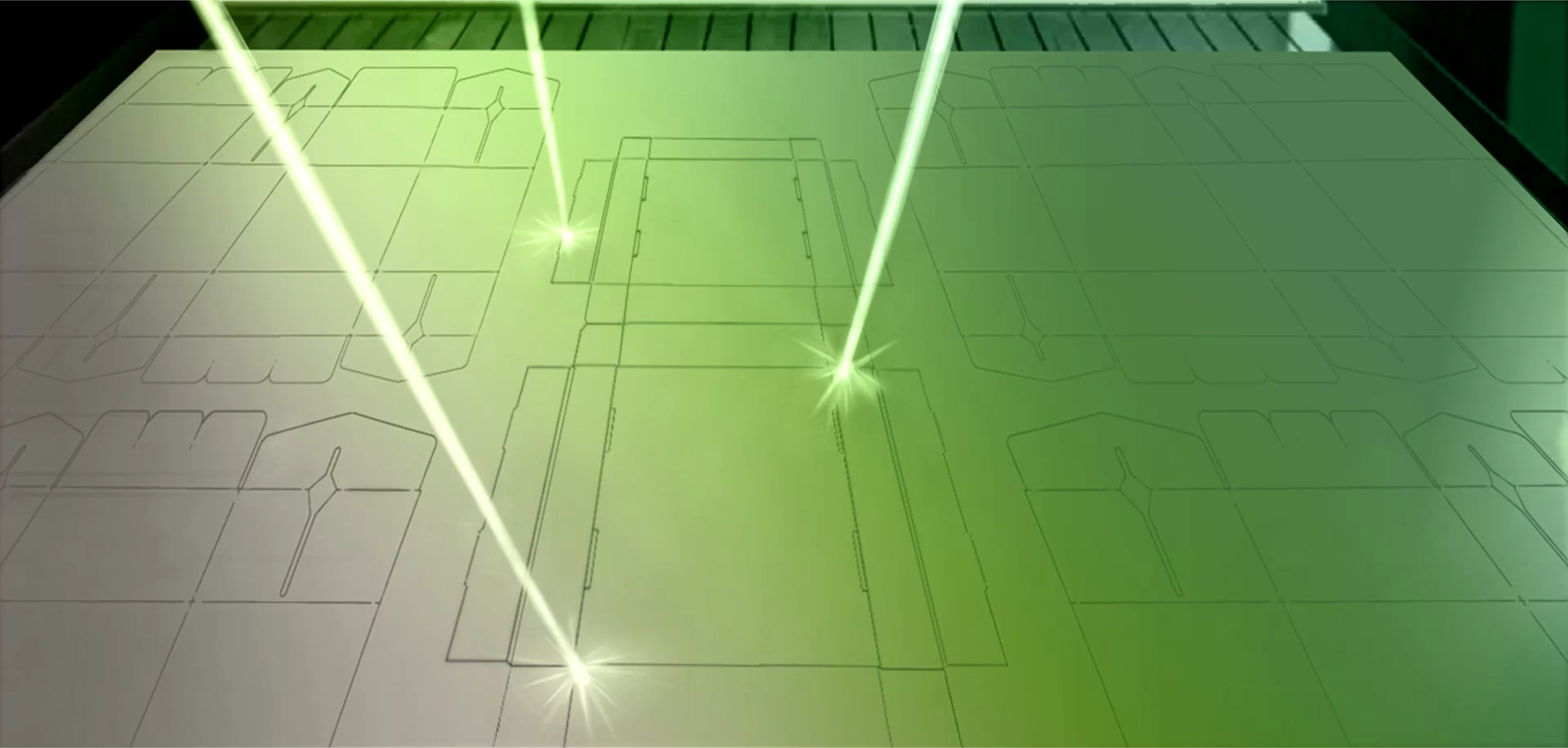

Beam 3

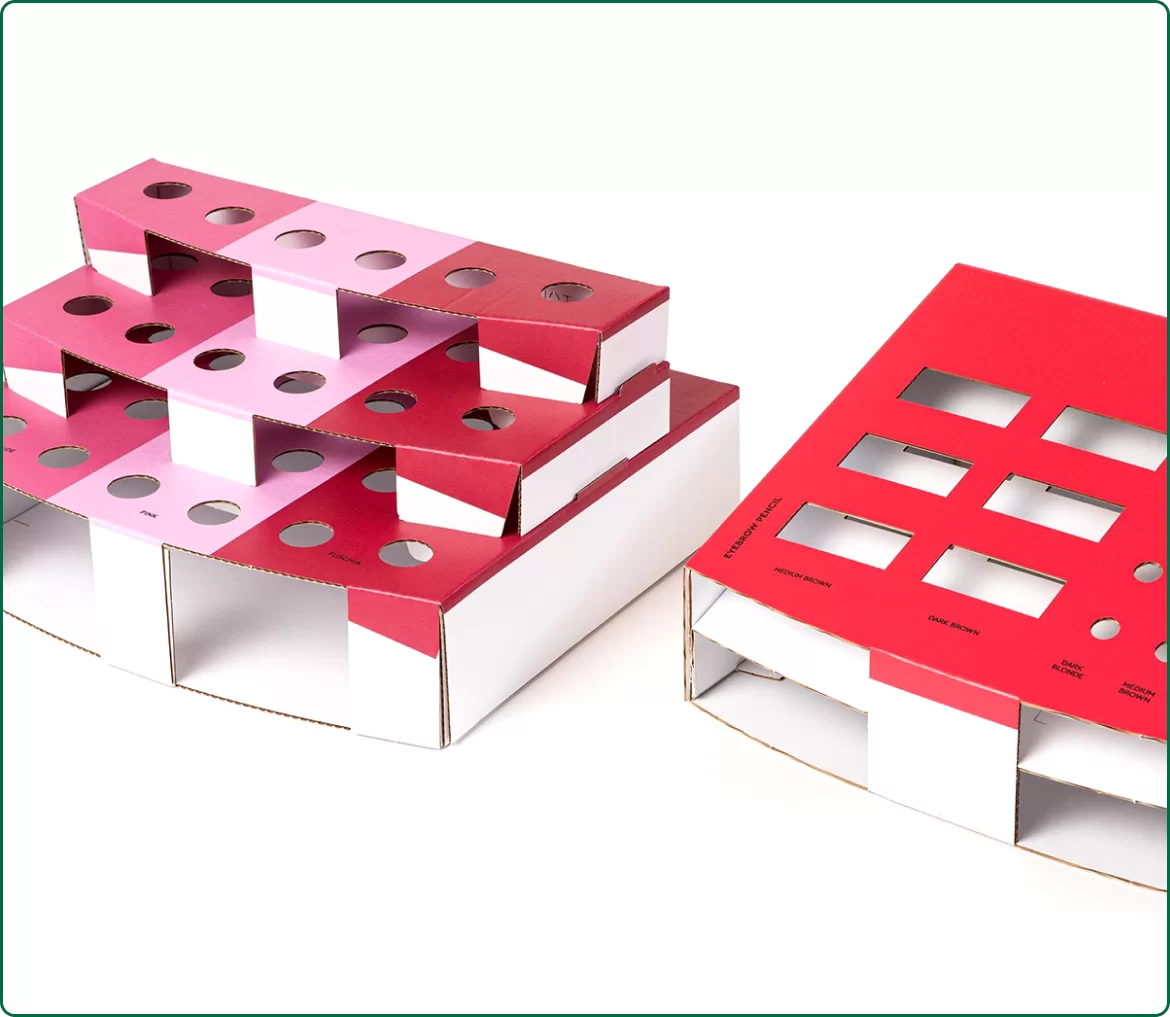

Digitally die cut 10 folding

carton jobs in an 8 hour shift!

Beam 3

Digitally die cut 10 folding

carton jobs in an 8 hour shift!

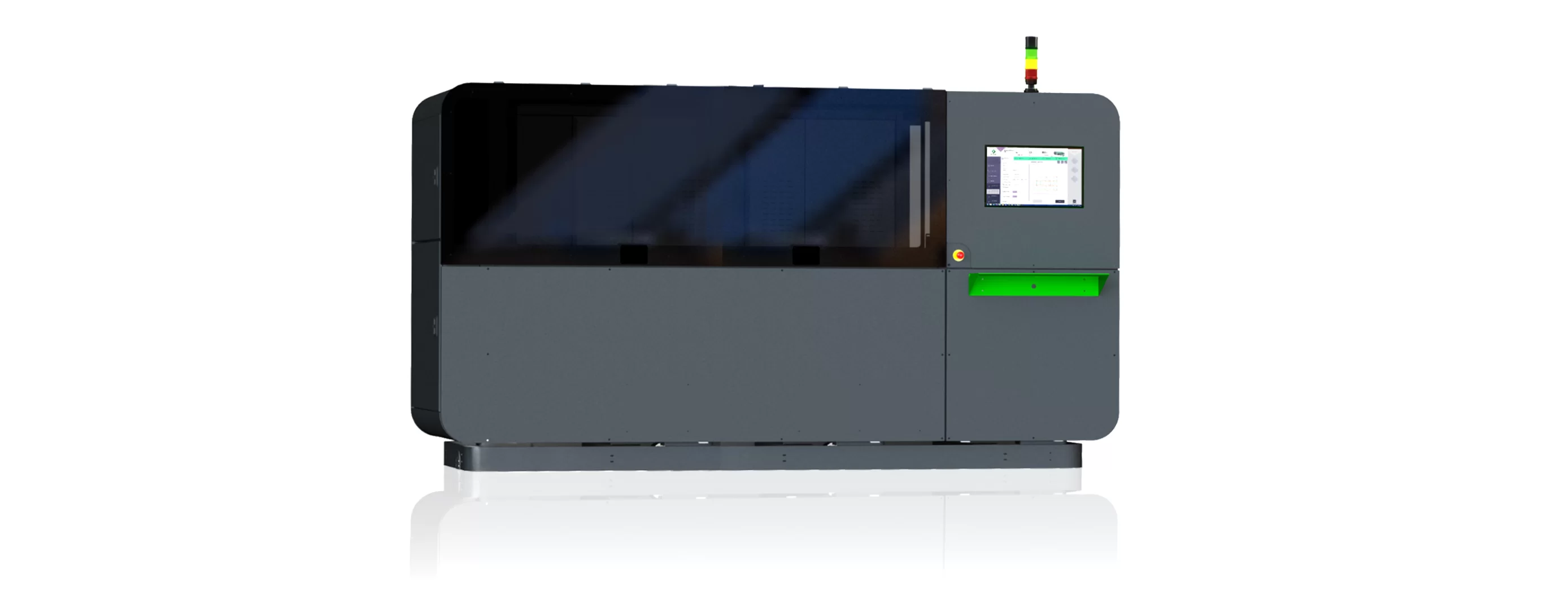

Highcon Vulcan*

Revolutionizing high value and

small batch corrugated production

*Internal R&D codename

True Digital Die Cutting

Laser cutting, digitally driven mechanical

creasing and digital stripping

Mainstreaming Digital

Die Cutting

See the new Highcon Beam 3 and Highcon

Beam Writer in action for the first time!

Join Highcon at drupa 2024: May 28 - June 7, 2024 | Hall 9, booth B24